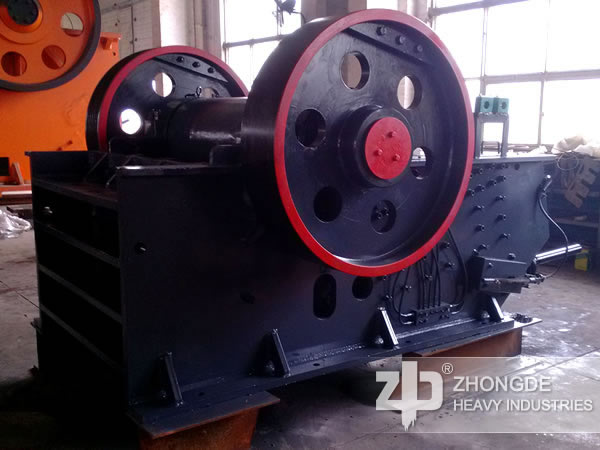

Jaw crusher, and jaw broken machine, jaw broken, such as short, is the advent of early, technologically mature crusher type, compared to other crusher, its structure is simpler, and has a strong, durable, long life, environmental protection, crushing ratio, energy saving, high yield and other advantages.

It is worth mentioning that 69 jaw breaker is a kind of machine with universal model and moderate production capacity. It is used for crushing various kinds of rocks with compressive strength of 147-245mpa. It is widely used in metallurgy, chemical industry, sand and stone, construction, transportation and other industrial sectors. So what's the yield per hour of 69 jaw breaker? The editor is for you.

69 jaw breaker is the abbreviation of pe-600 x 900 jaw crusher. It is responsible for the rough crushing of all kinds of mineral materials.

69 jaw breaker, the external dimension (length x width x height) is 2190x2206x2300mm, the total weight of the body is 17t, and the motor power is 6P 55Kw. The size of the official feed port is 600x900mm, and the particle size of feed can be allowed to be 500mm under ideal conditions. However, it is generally not recommended for customers to deliver the stone with such a large diameter, and it is better to use < 500mm. In addition, the adjustment range of the discharge port of the equipment is 65-160mm, the rotation speed of the eccentric shaft is up to 250r/min, and the processing capacity per hour is 50-180t under the principle. For stone materials of different types, different humidity and different hardness, the output may be different at that time.

69 Jaw crusher Expected capacity is generally within the fixed range (50-180t/h), in fact, the equipment capacity and crushing stone, operating mode, day-to-day maintenance and other factors are closely related, reasonable consideration of the relationship between these, to help improve equipment capacity.

The hardness, humidity, density, friability and particle size of crushing stone will affect the productivity of equipment. For example, the greater the hardness, the more difficult the crushing, its capacity may be lower.

Reasonable, scientific operation mode, operating conditions, will help 69 jaw broken machine better and more efficient, smooth operation, to ensure the steady increase in production capacity, this requires on-site operation must undergo professional training, a comprehensive understanding of equipment performance, operating details.

In normal work, attention should be paid to the maintenance of 69 jaw breaker, timely inspection and replacement of vulnerable parts, and regularly add and supplement lubricating oil to ensure that the crusher always maintains a good, high-speed running state.

Under general circumstances, 69 jaw broken machine as long as the attention to daily operation, maintenance, its crushing effect, capacity will be good, to reach daily 1000 tons will not be a problem at all, more about 69 jaw broken machine or other models jaw broken machine capacity introduction, at any time online consulting customer service!