Vertical Shaft Impact Crusher can also be called sand-making machine, is an international advanced level of high-energy low energy consumption impact break, its performance in a variety of ore-crushing equipment plays an irreplaceable role, is currently the most effective, practical and reliable gravel machine. The equipment is a stone stoning principle, widely used in construction, water conservancy and electric industry, applied to the river Pebbles, pebbles, granite and other materials. This paper briefly introduces the structure, application, advantages and maintenance of the vertical shaft impact crusher .

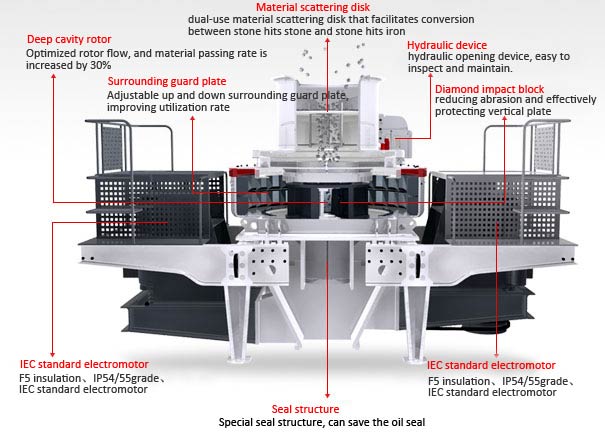

1. Vertical shaft impact crusher is generally by: feed mouth, distributor, vortex crusher cavity, impeller, and the combination of the main shaft.

2. Vertical shaft impact crusher is widely used in metal and non-metallic ores, as well as cement, refractories, abrasives, glass raw materials, building aggregates;In addition there are some ore tailings, stone debris of artificial sand, building aggregates, road surface materials, bedding materials, asphalt concrete and cement aggregate production, as well as a variety of metallurgical slag finely and coarse grinding.

1.Vertical shaft impact crusher for medium and hard, hard and abrasive materials such as silicon carbide, Emery, sintered aluminum-vanadium soil, magnesia, etc., than other types of crusher more advantages.

2. Its structure is novel, unique, simple, high yield, and large crushing ratio.

3. the equipment small size, easy to operate, installation and maintenance convenience.

4. the equipment has plastic function, the product is cubic-shaped, bulk density.

1. the hardness of the material: in general, the more hard material in the process of sand making the more difficult, and then vertical shaft impact crusher equipment damage degree is larger, more likely to cause damage to the machine.

2. the viscosity of the material: the greater the viscosity of the material, the easier it is to adhere. The material with high viscosity will adhere to the inner wall of the sand chamber in the vertical shaft impact crusher . If it cannot be cleaned in time, it will affect the working efficiency of the vertical shaft impact crusher , and in severe cases it may also affect the normal operation of the vertical shaft impact crusher . Therefore, when selecting materials, it must be noted that the viscosity of the materials is not too large.

3. Humidity of the material: When the moisture contained in the material is large, the material adheres easily to the inner wall, which can easily cause blockage during the process of cutting, which results in a decrease in the sand production capacity. Therefore, the material must be strictly controlled when the material is selected. Humidity, if the humidity of the selected material is too large, sunlight or air drying can be used to reduce the moisture in the material, which will greatly reduce the impact on the vertical shaft impact crusher .

Firstly, regular downtime open observation doors to observe the impact of the internal wear of sand-making machine, check the center into the material pipe, cone cap, impeller, the lining of the lower liner, circumference shield, wear-resistant block wear, if it is found inside wear, should be replaced or repaired in a timely manner, to ensure that the production of equipment does not affect.

Secondly, the vertical shaft impact crusher has a long duration of work and should be added with lubricant to ensure that the machine will not wear out or be damaged due to a long time.

Finally, when using this product, it should be based on the instructions in the manual, do not blindly operate, you can consult the manufacturer.

With regard to how to maintain the vertical shaft impact crusher , Zhongde Heavy Industries has a strong service team in pre-sale, in-sale, and after-sale, and has professional technicians who can promptly and quickly answer questions for you.