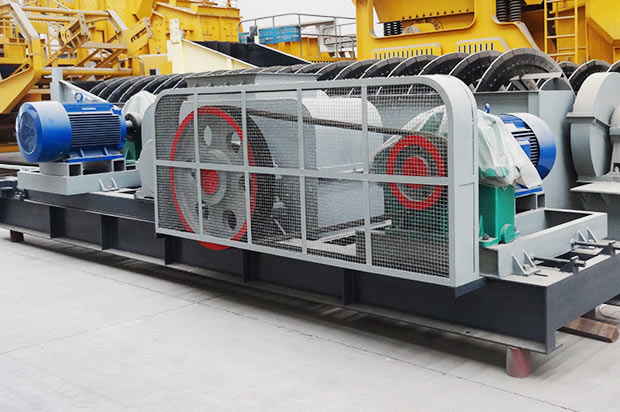

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc.

Feeding Size: ≤25-≤100mm

Processing Capacity: 5-100t/h

Get more information about theRoller Crusher

Roller crusher has various models, which is mainly used to complete the medium and fine crushing of medium hardness materials, and it is often used for processing materials after coarse crushing. However, for coal and coke with various hardness, it can also be used for the coarse crushing process.

Roll crusher is not suitable for crushing flat or sheet shape materials, because the material is easy to fall down from the roller gap, which not only reduces the production efficiency, but also reduces the qualified rate of the finished product.

The spring safety measures are configured on the roller of roller crusher. When the materials which cannot be crushed enter into the rollers, the spring will exert its protective ability. Compression leads to the increase of roller spacing, when the impurities are removed, the roller can return to the original distance to ensure normal production.

1. Low consumption, environmental protection.

2. Effective protection measures, safe and stable operation of the machine.

3. The discharging size can be adjusted, which only needs to adjust the roller gap.

4. It is equipped with dust inside board, which effectively avoids harmless dust on equipment, so it has longer service life.

Because of its unique structure and diverse types, roll crusher is widely used in the industrial sectors of mineral processing, chemical industry, cement, building materials industry, etc. Especially in the coal industry, roller crusher can be used for crushing raw ore after the removal of iron and impurity without removing gangue. The finished materials has uniform particle size, low over crushing ratio, thus simplifying the process of coal preparation and reducing the investment and production cost.

| Model | Roller diameter (mm) |

Roller Width (mm) |

Input Size (mm) |

Dischargine Gate (mm) |

Capacity (t/h) |

Power Models | Motor Power (KW) |

| 2PG0425 | Φ400 | 250 | ≤25 | 2-8 | 5-10 | Y132M-6 | 5.5×2 |

| 2PG0640 | Φ600 | 400 | ≤25 | 2-8 | 10-20 | Y160L-4 | 15×2 |

| 2PG0740 | Φ700 | 400 | ≤25 | 2-8 | 15-30 | Y200L-4 | 30×2 |

| 2PG0850 | Φ800 | 500 | ≤25 | 2-8 | 20-40 | Y225M-4 | 45×2 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Input Size (mm) |

Dischargine Gate (mm) |

Capacity (t/h) |

| 2PG0425 | ≤25 | 2-8 | 5-10 |

| 2PG0640 | ≤25 | 2-8 | 10-20 |

| 2PG0740 | ≤25 | 2-8 | 15-30 |

| 2PG0850 | ≤25 | 2-8 | 20-40 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan

Submit a business inquery online or visit the nearest projexon office.

contact usCopyright: @ luoyang zhongde heavy industries Co., LTD.Privacy PolicyPrivacy Policy