Ore beneficiation plant can be used for separating various ores such as iron, copper, gold, nickel iron, chromium, lead, zinc, tin, antimony, mica, feldspar, quartz, siderite, limonite, hematite ore, iron mirror, etc.

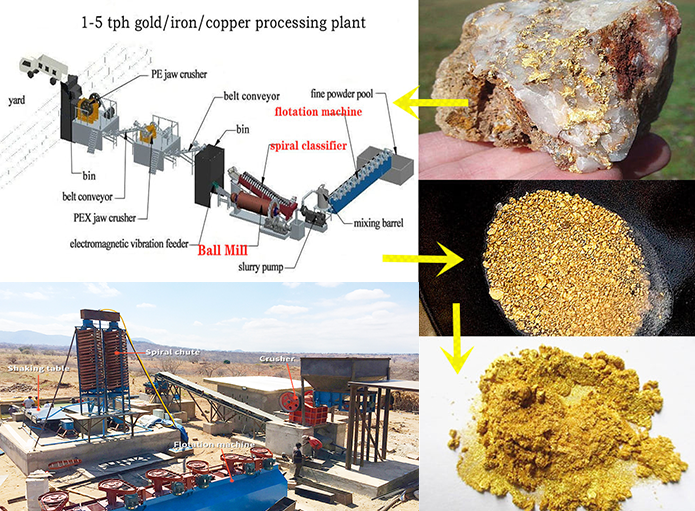

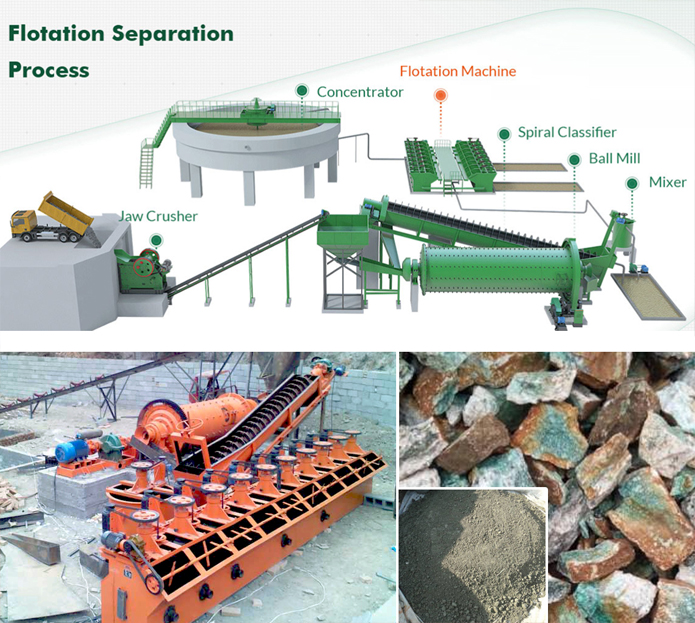

Main Equipment : Jaw crusher, flotation machine, classifier, ball mill, etc.

Production Capacity: 10-430t/h

Get more information about theOre Beneficiation Plant

Ore Beneficiation Plant is also known as ore dressing plant, which is made up of jaw rusher, ball mill, classifier, magnetic separator, flotation machine, thickener and drying machine, and these equipment can be composed of a complete ore dressing line with feeder, elevator and conveyor.

1. According to the ore properties, it can be divided into gold separation equipment, iron separation equipment, copper, manganese, chromium, vanadium, zinc, aluminum, nickel, cobalt, tungsten, tin, antimony and other full sets of mineral processing technology according to the different characteristics of different ores.

2. Gravity separation, magnetic separation, flotation separation and many other kinds of mineral processing technology can be chosen according to different production lines.

The mined ores should be firstly crushed by the jaw crusher, and then sent to the ball mill for grinding through the elevator and feeder after being crushed into the reasonable size. After the grinding process, the ore mixture will be classified by the classifier.

1. When the mineral mixture goes through the magnetic separator, due to the different coefficients of various minerals, the magnetic materials will be separated through magnetic force and mechanical force.

2. When the mineral mixture passes flotation machine, according to the different surface physical and chemical properties of mineral particles, the minerals will be separated by their flotation properties. After sorting, the materials will go through the initial concentration by the thickener; finally the dry minerals can be gained after drying.

1. High processing capacity, which can process 1500-3000 tons ore per day.

2. The tailings grade can be controlled to more than 1.2.

3. For soft ore and sand mine, they can be directly crushed into a certain fineness.

4. Low energy consumption, the power is only 6KW, which greatly reduces the production cost.

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan

Submit a business inquery online or visit the nearest projexon office.

contact usCopyright: @ luoyang zhongde heavy industries Co., LTD.Privacy PolicyPrivacy Policy