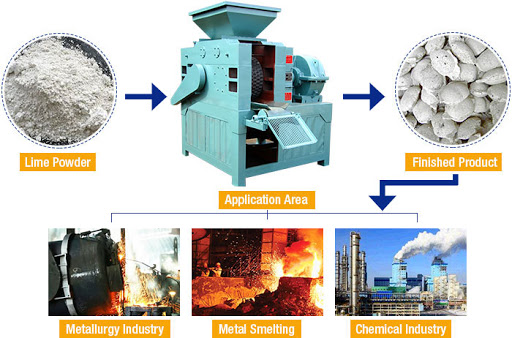

Lime powder briquette machine is mainly used to make lime powder into briquettes. Its most significant feature is that it can press the dry powder directly into briquettes.

Capacity: 1-30T/H

Power: 5.5-132KW

Get more information about theLime Briquetting Machine

Lime powder briquette machine is mainly used to make lime powder into briquettes. Its most significant feature is that it can press the dry powder directly into briquettes.

The lime powder briquette machine can reduce dust, control material volume, recycle the lime powder and improve its transport properties.

Lime briquetting machine is suitable for quicklime powder, dolomite powder, copper concentrate, chromium ore, manganese ore powder, laterite-nickel ore, lead and zinc scrap, bauxite, non-ferrous metal powder, refractory materials, ceramic materials, iron powder materials in steel plant, converter sludge, ferric oxide powder, iron sheet, aluminum skimmings, activated alumina, etc.

The choice of binder: the quality of binder directly influences the hardness and density of briquettes, and also affects the production cost. So it is important to choose a kind of binder that has easy access, good effect and low price.

Raw material uniformity degree: the particle size and hardness will influence the pressing effect and efficiency of lime powder briquette machine, therefore the uniformity of raw material will directly influence the briquettes quality. So before the raw material enters the lime powder briquette machine, you need to make it to proper particle size.

Moisture and drying technology: sometimes the raw material can be too wet or too dry; if directly put into the briquette machine, it will cause raw material adhesion or broken briquettes. Therefore, the raw material must be kept to certain moisture content.

| Model | Roller Diameter (mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan

Submit a business inquery online or visit the nearest projexon office.

contact usCopyright: @ luoyang zhongde heavy industries Co., LTD.Privacy PolicyPrivacy Policy