Ball mill is suitable for grinding ores and other materials and is widely used in non-ferrous metal mining, non-metallic mining building materials, the chemical industry, coal, cement, silicate products, refractory materials, and glass ceramics, etc. It is divided into dry and wet grinding methods.

Feeding Size: ≤25mm

Capacity: 0.65-615t/h

Get more information about theBall Mill

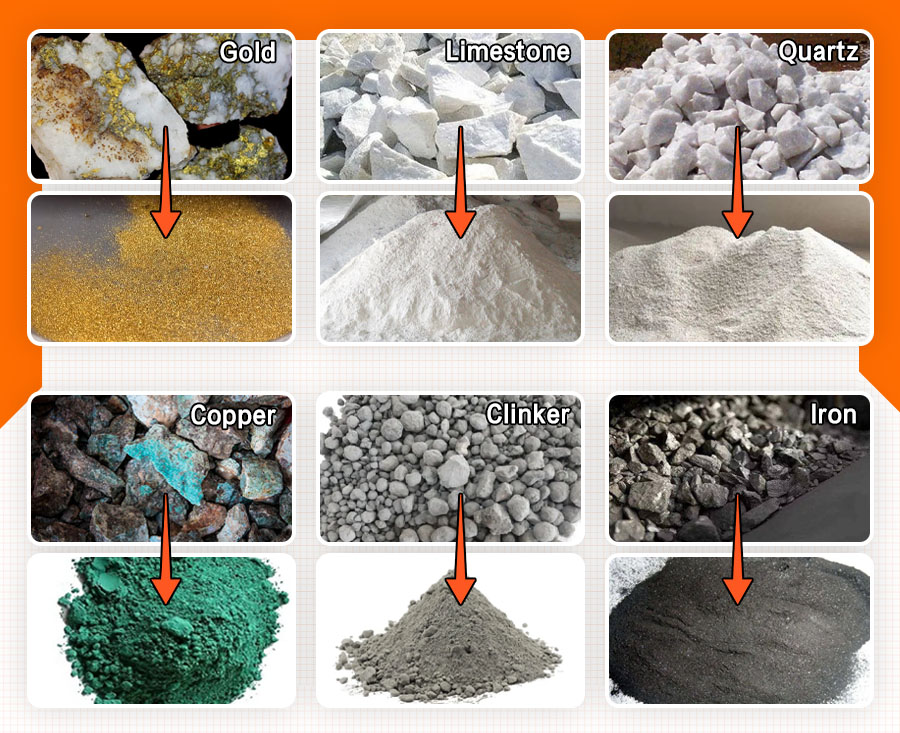

Wet type ball mill is suitbale materials mainly on beneficiation plant such as gold ore, iron ore, copper ore, gold ore, aluminum ore, manganese ore, magnetite, chrome ore. Dry type ball mill is suitbale mateirals such as limestone, gypsum, slag, granite, quartz, barite, bentonite, calcite, coal, dolomite, feldspar, etc.

Application areas:It is widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and non-ferrous metal dressing, and glass and ceramics, with dry or wet abrasive ore and other abrasive materials. You decide the working way of small ball mill machine according to your material and discharging way.

Limestone Ball Mill Customer Case

Customer Location: Pakistan Process Material: Limestone Capacity: 15tph Discharge size: 200 mesh.

Customer feedback: I searched on Google for ball mill and found Zdzg company. we contacted Zdzg company sales engineer and sent the details of our project. After 1 hours online vedio, Zdzg company offered a suitable solution and the flow chart. This ball mill grinding line for processing limestone has worked for us for about half years with all cost recovered and benefits increased.

Gold Ore Ball Mill Customer Case

Customer Location: Tanzania Process Material: Rock Gold Capacity: 25tph Discharge size: 45 micron.

Customer feedback: We are a gold mining company on Dar es Salaam. We went to China to visit the Zdzg company before purchasing. They have 3 factories and are very large, which strengthens our confidence in purchasing.

1.The production process is strictly controlled, and only products that pass inspection can leave the factory.

2.We provide you with solutions, model introduction, quotation, and process design.

3.Deliver machines strictly on time.

4.We provide parts and after-sales guarantee.

We have been devoted to mineral processing technology research for more than 40 years. Mature production concept, professional technical research and development team are available for you to supply the high quality ball mill equipment!

We export to more than 200 countries: Tanzania, South Africa, Australia, UK, Jordan, Saudi Arabia, Indonesia, Malaysia, Albania, Turkey, South Africa, and other countries.

You can come and visit our factory at any time, we provide you with warm reception services and product display services.

Ball mills are divided into large, medium and small models. We supply different models to small miner such as 1 tph, 5 tph, 8 tph and large mining compay such as 30 tph, 50 tph, 100 tph, 200 tph. We customized ball mill according to your different needs to minimize your costs.

Sincerely welcome old and new users visit and purchase from our company, at that time we will provide you the high-class ball mill machine and perfect after-sale service.

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | As per process conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | As per process conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | As per process conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |

| Model | Feeding size (mm) |

Capacity (t/h) |

| Ф900×1800 | <20 | 0.65-2 |

| Ф900×3000 | <20 | 1.1-3.5 |

| Ф1200×2400 | <25 | 1.5-4.8 |

| Ф1200×3000 | <25 | 1.6-5 |

| Ф1200×4500 | <25 | 1.6-5.8 |

| Ф1500×3000 | <25 | 2-5 |

| Ф1500×4500 | <25 | 3-6 |

| Ф1500×5700 | <25 | 3.5-6 |

| Ф1830×3000 | <25 | 4-10 |

| Ф1830×4500 | <25 | 4.5-12 |

| Ф1830×6400 | <25 | 6.5-15 |

| Ф1830×7000 | <25 | 7.5-17 |

| Ф2100×3000 | <25 | 6.5-36 |

| Ф2100×4500 | <25 | 8-43 |

| Ф2100×7000 | <25 | 12-48 |

| Ф2200×4500 | <25 | 9-45 |

| Ф2200×6500 | <25 | 14-26 |

| Ф2200×7000 | <25 | 15-28 |

| Ф2200×7500 | <25 | 15-30 |

| Ф2400×3000 | <25 | 7-50 |

| Ф2400×4500 | <25 | 8.5-60 |

| Ф2700×4000 | <25 | 22-80 |

| Ф2700×4500 | <25 | 26-90 |

| Ф3200×4500 | <25 | As per process conditions |

| Ф3600×4500 | <25 | As per process conditions |

| Ф3600×6000 | <25 | As per process conditions |

| Ф3600×8500 | <25 | 45.8-256 |

| Ф4000×5000 | <25 | 45-208 |

| Ф4000×6000 | <25 | 65-248 |

| Ф4000×6700 | <25 | 75-252 |

| Ф4500×6400 | <25 | 84-306 |

| Ф5030×6400 | <25 | 98-386 |

| Ф5030×8300 | <25 | 118-500 |

| Ф5500×8500 | <25 | 148-615 |

NOTE: You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan

Submit a business inquery online or visit the nearest projexon office.

contact usCopyright: @ luoyang zhongde heavy industries Co., LTD.Privacy PolicyPrivacy Policy